What is Aqueous Coating in Packaging & Printing?

Aqueous coating is a special water-based liquid that people use to protect and shine paper products like brochures, business cards, and book covers. First, workers print the design on the paper, and then they apply the coating to make it look glossy or matte.

What Are Packaging Inserts?

Packaging inserts are extra items that companies put inside a package along with the main product. These inserts include thank-you notes, discount coupons, free samples, instruction manuals, or even small gifts. Companies add them to make customers happy, provide helpful information, and encourage people to buy again.

What Is Varnish Coating in Packaging & Printing?

Varnish coating in packaging is a thin layer added to the surface of printed materials, like boxes or labels, to protect and enhance them. It improves both the appearance and durability of the packaging. Let me explain how it works.

What is Corrugated Packaging?

Corrugated packaging is a type of box or container made from special cardboard. This cardboard is unique because it has three layers: an inside liner, an outside liner, and a wavy layer in the middle called fluting. Because of this, the fluting makes the packaging strong and lightweight at the same time.

What is Spot UV Printing? Adding Shine and Elegance to Your Packaging

Spot UV printing is a technique that enhances the look and feel of designs by adding a shiny, glossy finish to specific areas like logos, text, or patterns. It works by applying a clear liquid coating to the selected parts and then using ultraviolet (UV) light to dry and harden them quickly. This process creates a stunning contrast between the shiny and matte areas, making the design more eye-catching and professional. Spot UV is widely used in packaging, business cards, invitations, and luxury products to create a premium and memorable impression.

Soft Touch Coating vs. Soft Touch Lamination: What is the Difference?

The finish of printed materials makes a big difference, and it can truly affect how people see your product.

In today’s world, where looks matter more than ever, the outside of your packaging is extremely important. That is why putting effort into how it looks can make your product more appealing. Moreover, it can help your brand stand out positively.

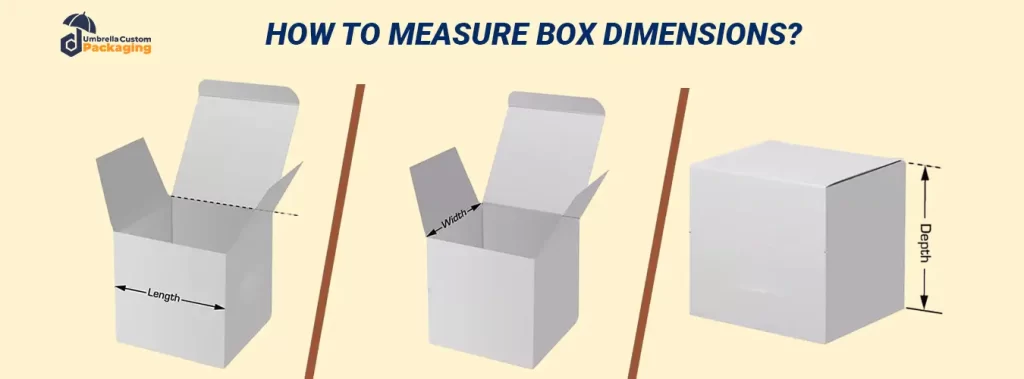

How to Measure Box Dimensions?

Measuring a box may seem simple at first, but when it comes to custom packaging, you obviously need to focus on accuracy. To get the best results, you must pay attention to every single detail. While the process is not complicated, taking the time to measure correctly ensures your packaging fits perfectly and protects your product effectively.

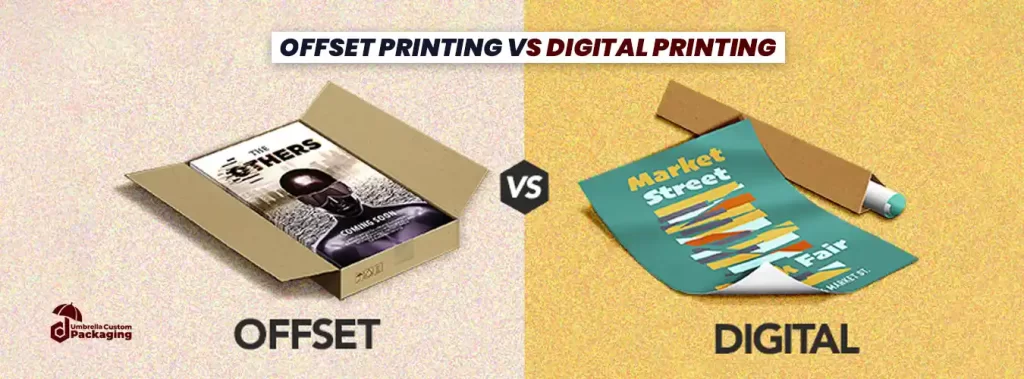

Choosing between Digital and Offset Printing for Packaging: Which is Right for You?

When choosing between digital and offset printing for packaging, consider factors such as the number of packages, cost, and the need for custom designs. For large orders, offset printing is the better option as it becomes more cost-effective with higher quantities while maintaining excellent quality.

How to Properly Seal Mylar Bags: Complete Guide

Mylar bags are strong and flexible storage bags made from a special type of plastic called BoPET (biaxial-oriented) polyethylene terephthalate). These bags have shiny, reflective surfaces and are great at keeping air and moisture out. Because of these qualities, people often use these bags for long-term food storage and preservation.

What is Cosmetics Packaging?

Cosmetics packaging is the material and design used to store and present beauty products. It keeps products like creams, perfumes, lipsticks, and shampoos safe and fresh. However, it also plays a big role in how the products look and feel to customers.