Menu

Close

The demand for corrugated boxes has risen significantly in recent years. In 2021, the global corrugated box market was valued at approximately $256 billion. This growth reflects the increasing reliance on e-commerce and shipping. Corrugated boxes are lightweight yet sturdy, making them ideal for various shipping needs. They provide excellent protection during transit and handling, which is critical for businesses striving to maintain product quality.

However, not all corrugated boxes are created equal. There is a wide range of options, including single-wall, double-wall, and custom designs. Each type serves different purposes and needs. Companies must choose wisely to optimize their packaging solutions. Failing to select the right corrugated box may lead to damage and increased costs. This decision is not as straightforward as it seems.

Furthermore, sustainability concerns are changing the landscape of packaging solutions. Consumers increasingly prefer recyclable and environmentally friendly materials. Therefore, businesses need to consider how their choice of corrugated boxes affects their brand image and environmental footprint. Balancing functionality and sustainability remains a challenge. Understanding the top types of corrugated boxes can guide companies toward better shipping and packaging solutions.

Corrugated boxes are essential for shipping various products. They offer protection and stability during transport. Different types of corrugated boxes suit various needs. For example, regular slotted containers are widely used. They are strong and economical. These boxes work well for large, heavy items.

Another type is the die-cut box. This box can be customized to fit specific products. It looks good and can save space. Retailers often use these for showcasing goods. In contrast, shipper boxes are designed for a universal fit. They protect items and can stack easily. This type is usually less costly.

Choosing the right type of box can be challenging. Sometimes, businesses overlook the importance of box strength. A flimsy box can lead to damaged goods. Additionally, not all products require heavy-duty boxes. Assessing the specific needs of your products is vital. Making informed choices can prevent issues in the shipping process.

| Type of Box | Description | Common Uses | Strength |

|---|---|---|---|

| Regular Slotted Container (RSC) | Most common type with flaps that meet in the middle. | Shipping various goods, retail packaging. | Medium strength. |

| Half Slotted Container (HSC) | Similar to RSC but without one set of flaps. | Display boxes, large items. | High strength. |

| Die-Cut Box | Custom-shaped box that can contain various items. | Retail products, gifts. | Variable strength depending on design. |

| Multi-Depth Box | Can be cut down to multiple sizes for various needs. | Versatile packaging for e-commerce. | Average strength. |

| Side Load Box | Designed for loading from the side, maximizing space. | Apparel, automotive parts. | High strength. |

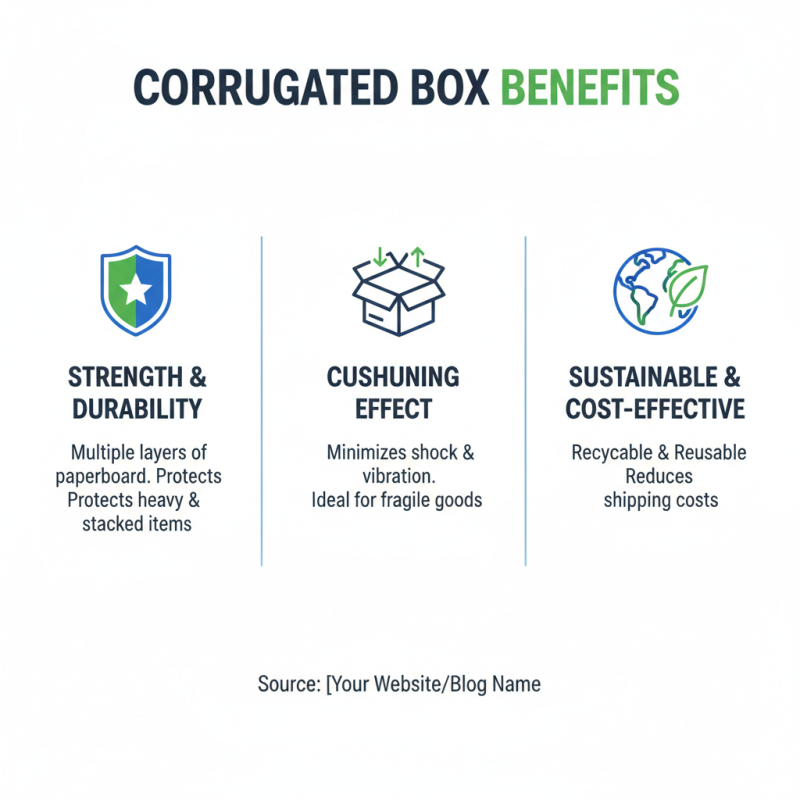

Corrugated boxes offer a variety of benefits for packaging and shipping. Their design features multiple layers of paperboard, providing excellent strength and durability. This makes them an ideal choice for transporting fragile items. The cushioning effect minimizes the risk of damage during transit, which is a significant concern for many businesses.

It’s also worth noting that corrugated boxes are lightweight. This reduces shipping costs and makes handling easier. However, some might overlook the environmental impact. While many corrugated boxes are recyclable, not all are disposed of properly, leading to waste. Additionally, the production process can consume considerable resources.

Aesthetically, corrugated boxes can be customized. Brands can print logos or designs on them, enhancing visibility. However, balancing cost-effective solutions with visual appeal can be challenging. Sometimes, the focus on functionality overshadows the design, leaving a lackluster impression on customers.

When it comes to shipping and packaging, selecting the right grade of corrugated box matters. The types range from single-wall to double-wall options. Single-wall boxes are lightweight and cost-effective, making them ideal for less fragile items. However, they may not offer enough protection during transit. This can lead to damaged goods, which could result in unhappy customers.

Double-wall boxes provide additional strength. They work well for heavier or more delicate items. The two layers of fluting create extra cushioning. This added durability can reduce the likelihood of breakage. Yet, these boxes are often more expensive and heavier, affecting shipping costs. It’s essential to weigh these trade-offs when choosing the right box.

Another option is triple-wall boxes. These are the strongest and can handle the heaviest loads. They are perfect for industrial shipping, but they can take up significant warehouse space. Plus, their weight can increase shipping fees. Businesses must carefully consider the actual needs of their products. Finding the right balance is crucial for cost-effective and secure shipping solutions.

When selecting corrugated boxes for shipping and packaging, various factors come into play. One essential element is the box's size. A box too large can lead to shifting during transit. Conversely, if it's too small, it may not hold the contents securely. Finding that perfect fit requires careful measurement, so pay attention to dimensions.

Another crucial aspect is the type of corrugated material used. There are single-wall and double-wall options. Single-wall boxes are lightweight and suitable for lightweight items. Double-wall boxes offer extra protection, making them ideal for heavier goods or fragile items. The weight capacity is another consideration. Always assess what will be packed inside and select a box that can handle the weight.

Additionally, consider the box's design and functionality. Some boxes come with built-in features like handles or are easy to assemble. This can enhance user experience during packing and unpacking. Keep in mind that not all designs suit every product. Experimenting with different box styles could lead to unexpected challenges, like difficulties in storage or shipping. It's essential to find a balance between design and practicality for your specific needs.

Sustainable packaging is increasingly important in the shipping industry. Corrugated boxes made from recycled materials are a popular option. According to a 2022 industry report, over 90% of corrugated packaging is recyclable. This statistic highlights the environmental benefits of using corrugated materials.

Biodegradable options are also available. These incorporate natural fibers and adhesives that break down easily. Reports indicate that using biodegradable packaging can reduce carbon emissions by up to 30%. Many companies are shifting towards these sustainable solutions. They recognize the growing consumer demand for eco-friendly practices.

However, the journey to sustainability can be complex. Some manufacturers face challenges sourcing ethical materials. Others struggle with the costs associated with transitioning to greener options. It’s crucial to find a balance between sustainability and affordability. This is an ongoing issue many in the industry are currently navigating. Investing in sustainable alternatives isn't just a trend; it's becoming a necessity.

This chart illustrates the distribution of different types of corrugated boxes used for shipping and packaging solutions. The Regular Slotted Container (RSC) takes the largest share, accounting for 40% of usage, reflecting its versatility and popularity among shippers.

We offer Packaging Boxes delivered to your door. Secure, professional, and affordable, our custom made packaging boxes are guaranteed to protect and transport your valuable items. Our devoted team is always there to serve you.