Menu

Close

In the packaging industry, corrugated boxes play a crucial role. They provide strength and protection for goods in transit. According to packaging expert Dr. Emily Dawson, "Corrugated boxes are not just containers; they increase efficiency and sustainability." This highlights their importance in modern packaging solutions.

Corrugated boxes are lightweight yet durable. Their unique structure allows for stacking and smart logistics. Yet, not all corrugated boxes meet high standards. Some manufacturers cut costs, leading to weaker boxes. This can result in damaged products and losses.

While many businesses recognize the benefits, not everyone fully grasps their impact. Not all companies prioritize quality over price. Investing in better corrugated boxes can enhance brand reputation. Ultimately, understanding the purpose of corrugated boxes is essential for effective packaging.

Corrugated boxes play a crucial role in the packaging industry, especially in protecting products during shipment. The layers of corrugated material provide strength and cushioning. This design helps absorb shocks and impacts during transportation. A well-constructed box minimizes the risk of damage from rough handling or sudden drops.

Despite their durability, corrugated boxes have their drawbacks. They can be susceptible to moisture, which weakens their structure. If not stored properly, they may also lose shape. Additionally, not all boxes fit every product. Selecting the right size and type is essential. A poorly sized box can lead to unnecessary movement inside, increasing the chances of damage.

Moreover, environmental concerns around cardboard recycling must be acknowledged. While many boxes are recyclable, not all make it to recycling facilities. The industry has room for improvement in this area. Striving for better sustainability practices will enhance the overall effectiveness of using corrugated boxes. Future innovations should focus on improving both protection and eco-friendliness.

Corrugated boxes have revolutionized the packaging industry. Their design offers strength and durability. Unlike traditional packaging, they use multiple layers of paper. This makes them lightweight yet sturdy. Businesses benefit from reduced shipping costs. Corrugated boxes are easier to stack and store, maximizing space.

These boxes are also eco-friendly. Made from recycled materials, they can be recycled again. This reduces waste and environmental impact. However, not all corrugated boxes are created equal. Some may not withstand extreme conditions. Companies should choose the right type based on their needs.

Durability is a key advantage. Corrugated boxes can handle heavy loads without breaking. This protects products during transit. Yet, weak design or poor manufacturing can lead to failures. Businesses must pay attention to quality. Overall, corrugated boxes provide a reliable and effective packaging solution.

| Dimension | Corrugated Boxes | Traditional Packaging Solutions |

|---|---|---|

| Material Strength | High durability due to layered structure | Typically lower strength and more prone to damage |

| Weight | Lightweight, reducing shipping costs | Heavier materials increase transportation costs |

| Customization | Easily customizable in size and design | Limited customization options |

| Eco-Friendliness | Recyclable and biodegradable | Often made from plastic or non-recyclable materials |

| Protection | Offers better cushioning and protection | Less effective in protecting contents |

| Cost-effectiveness | Economically favorable for bulk packaging | Higher costs for quality materials |

The environmental impact of corrugated boxes in the packaging industry is significant. According to a study by the Sustainable Packaging Coalition, corrugated boxes account for 31% of the total packaging market. Their recyclability is a key factor. Approximately 70% of corrugated boxes are recycled in the United States. This reduces waste and supports sustainability.

Despite their benefits, challenges remain. The production of corrugated boxes requires energy and resources. Reports indicate that manufacturing processes contribute to greenhouse gas emissions. It’s crucial to evaluate the entire lifecycle of these boxes. While they are reusable and recyclable, the environmental toll of production shouldn't be overlooked.

Innovations in materials can help. Some companies are exploring eco-friendly alternatives. These alternatives might reduce the overall carbon footprint. However, transitioning can be tricky. Cost and availability are major barriers. The industry must balance functionality with sustainability. It's a complex puzzle needing ongoing reflection and improvement.

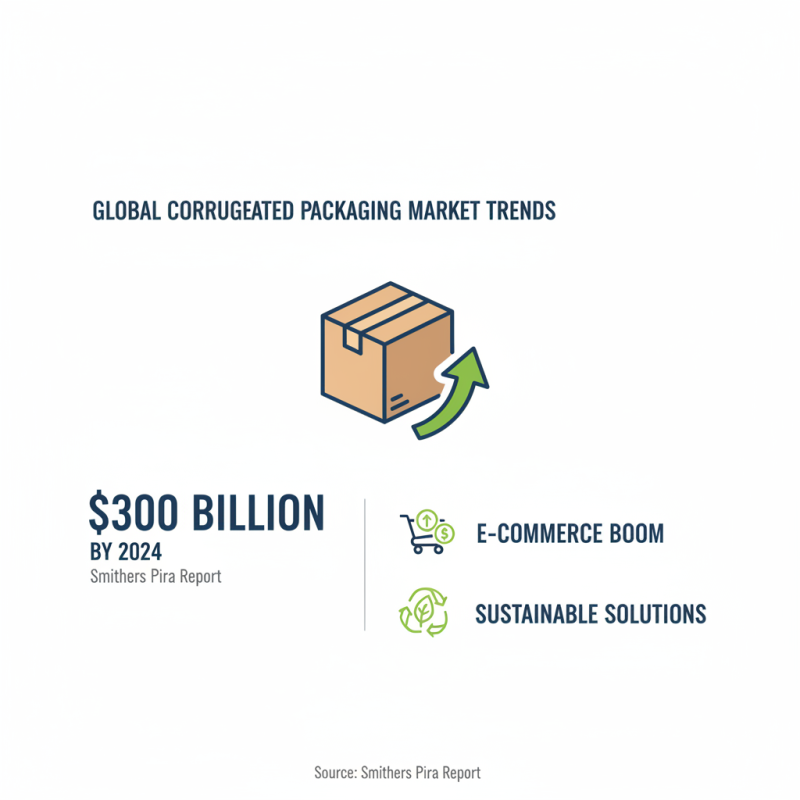

The corrugated box market has seen significant trends in recent years. According to a report by Smithers Pira, the global market for corrugated packaging is expected to reach $300 billion by 2024. The demand for these boxes is primarily driven by the rise in e-commerce and increased focus on sustainable packaging solutions.

In 2022, the North American corrugated box market accounted for approximately 30% of global consumption. This growth correlates with changing consumer preferences. Sustainable packaging is no longer just a trend; it's becoming a necessity. Many consumers are now looking for recyclable or biodegradable options in their packaging.

However, despite this upward trend, challenges remain. The supply chain disruptions from recent years still impact material availability. Various studies indicate that rising raw material prices can lead to increased costs for manufacturers. Also, not all corrugated packaging meets environmentally friendly standards, which raises questions about sustainability. There’s still room for improvement in sourcing practices across the industry.

Innovations in corrugated box design are transforming the packaging industry. With an increasing focus on sustainability, manufacturers are exploring eco-friendly materials. A recent report showed that over 40% of companies are now prioritizing recyclable materials in their packaging solutions. This shift reduces waste and enhances brand image.

Another trend is the integration of smart technology. Smart corrugated boxes equipped with sensors can track temperature and humidity. This ensures that products remain in optimal conditions during transit. Reports suggest that products transported in smart boxes experience up to 30% fewer damages. However, the implementation of this technology poses challenges, like increased production costs.

Design improvements are also notable. Companies are adopting more efficient shapes and sizes, optimizing space in shipping containers. Reports reveal that this can lead to a 20% reduction in shipping costs. While these advancements are promising, some companies struggle to keep up, risking obsolescence. Balancing innovation with affordability remains a continuous challenge in the industry.

We offer Packaging Boxes delivered to your door. Secure, professional, and affordable, our custom made packaging boxes are guaranteed to protect and transport your valuable items. Our devoted team is always there to serve you.