Menu

Close

Selecting the right cardboard shipping boxes is crucial for any business that relies on shipping. According to industry expert Sarah Thompson, "The right box can make or break your shipping experience." Businesses often overlook the importance of choosing the correct box type. This choice affects not only the product's safety but also shipping efficiency.

Choosing cardboard shipping boxes involves understanding your product’s dimensions and weight. Each box should be strong enough to handle its contents but not excessively bulky. The right fit reduces shipping costs and minimizes the chance of damage. However, many businesses still opt for generic sizes, which can lead to inefficiencies.

Reflecting on your needs is important. Are your current boxes creating delays or product returns? Are your packaging materials eco-friendly? These are essential questions to consider. The process may seem simple, but it demands careful thought and analysis to ensure that your cardboard shipping boxes meet your business requirements effectively.

Choosing the right cardboard shipping boxes starts with knowing your shipping requirements. What are you shipping? Understanding your products is crucial. Heavy items need sturdier boxes. Fragile products require cushioning and additional protection.

Tip: Measure your products accurately. Know the dimensions and weight before selecting a box. This ensures your items fit snugly. A loose fit may lead to damage during transit.

Consider the shipping distance as well. Longer distances might need more durable materials. Boxes can get damaged if they are not sturdy enough. Weather conditions also play a role. Rain or humidity can weaken cardboard.

Tip: Test different box types. Buy a few samples and conduct shipping trials. Check how they hold up during transport. This trial run can save you from costly mistakes later.

As you choose your boxes, keep in mind packaging materials. Those can affect the overall weight and cost of shipping. Striking a balance is essential. Always think ahead and adapt as your business grows.

This chart displays the preferences for different types of cardboard shipping boxes based on various business needs. The data represents the percentage of businesses that prefer each box type for their shipping requirements.

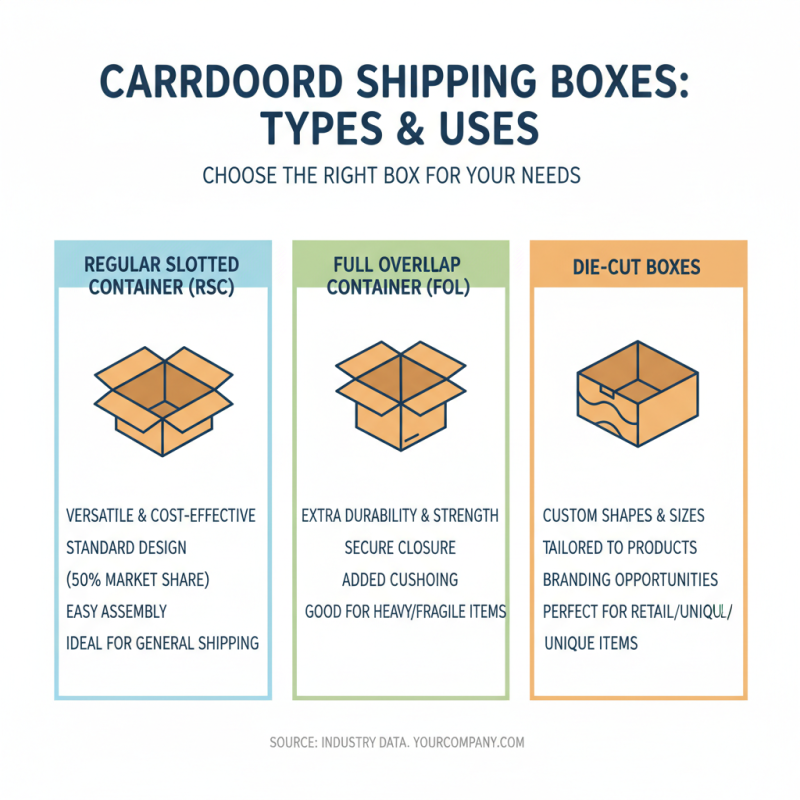

When selecting cardboard shipping boxes, understanding the various types available is crucial. The most common types are regular slotted containers (RSC), full overlap containers (FOL), and die-cut boxes. RSC boxes are versatile and cost-effective. They account for about 50% of the cardboard box market. Their design allows for easy assembly, making them popular for businesses of all sizes.

FOL boxes provide extra protection due to their overlapping flaps. This design is particularly beneficial for heavy or fragile items. Reports suggest that FOL boxes increase product safety during transit. However, they can be more expensive than RSC boxes. It's important to evaluate the trade-off between cost and protection based on specific shipping needs.

Die-cut boxes offer customization in size and shape. They can be tailored to fit products snugly, minimizing movement during shipping. Studies indicate that using custom die-cut boxes can reduce shipping costs by 30%. Yet, they often require longer lead times and can involve higher upfront costs. Balancing customization with budget constraints is a challenge many businesses face, highlighting the need for thorough analysis.

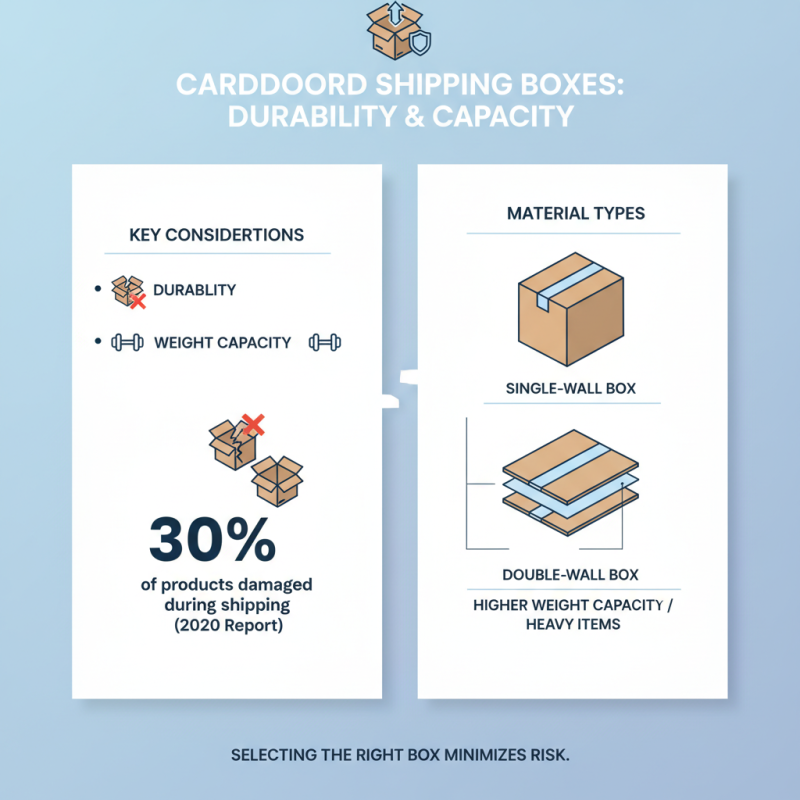

When evaluating cardboard shipping boxes, durability and weight capacity are crucial. According to a 2020 industry report, nearly 30% of products are damaged during shipping. Selecting the right box can minimize this risk significantly. The material composition affects structural integrity. For instance, single-wall boxes have a lower weight capacity, while double-wall boxes can typically support heavier items.

Weight capacity varies widely. Standard single-wall boxes hold about 30 to 65 pounds. A double-wall box can handle 60 to over 100 pounds, depending on dimensions. Specific testing methods, like the edge crush test (ECT), help determine box strength. Boxes with higher ECT ratings tend to resist crushing under weight better. Choosing a box with a suitable capacity is essential to avoid mishaps.

Some businesses overlook the importance of reinforcements, such as corner protectors or internal supports. Failing to use these can lead to box failure. Remember, not all packaging fits every item. Assess your product’s dimensions and weight before selecting. Even minor oversights can lead to increased costs or damaged goods.

When selecting cardboard shipping boxes, cost-effectiveness is crucial. Businesses often face budget constraints, especially when purchasing in bulk. The right choice can lead to savings and efficiency. However, balancing cost and quality can be tricky.

Tips: Always compare unit prices. Bulk purchases might seem cheaper, but hidden costs can emerge. Check for shipping fees and minimum order quantities. Sometimes, smaller orders from local suppliers can save money in the long run.

It's also important to consider box dimensions. A larger box costs more, both in materials and shipping. Oversized boxes can lead to increased costs, and may even result in product damage. Measure your products carefully. They deserve tailored packaging to ensure safety.

Lastly, don't shy away from asking suppliers for discounts on bulk orders. Many are willing to negotiate. Reflect on previous purchases for more insight. What worked? What didn’t? Your choices shape your business’s bottom line. Remember, every detail matters in logistics.

| Box Type | Dimensions (inches) | Weight Capacity (lbs) | Quantity per Bulk Purchase | Cost per Box ($) | Total Cost ($) |

|---|---|---|---|---|---|

| Regular Slotted Container (RSC) | 12 x 12 x 12 | 30 | 100 | 0.50 | 50.00 |

| Die-Cut Box | 10 x 10 x 10 | 25 | 200 | 0.75 | 150.00 |

| Multi-Depth Box | 15 x 15 x 15 | 40 | 150 | 1.00 | 150.00 |

| Sleeve Box | 8 x 8 x 8 | 20 | 250 | 0.60 | 150.00 |

| Flat Box | 14 x 4 x 10 | 15 | 300 | 0.40 | 120.00 |

When selecting cardboard shipping boxes, customization is key for branding and product protection. Customizing your boxes allows for unique designs that represent your brand. According to a recent industry report, 78% of consumers prefer products packaged in customized boxes. This strong preference highlights the importance of presenting your brand effectively.

Think about the box size and shape. If your product is fragile, opt for a design that offers enhanced protection. Studies show that 30% of products are damaged during shipping due to inadequate packaging. Adding cushioning elements, such as inserts, can minimize this risk. Customization can also include printing logos or brand messages, reinforcing your identity even before the customer opens the box.

However, budget constraints can limit customization options. Businesses should weigh the costs versus potential branding benefits. While a well-designed box can boost sales, over-spending can hurt profit margins. Finding the right balance between appearance and cost-effectiveness is crucial. Evaluate your needs carefully to ensure your packaging reflects your brand while protecting your products.

We offer Packaging Boxes delivered to your door. Secure, professional, and affordable, our custom made packaging boxes are guaranteed to protect and transport your valuable items. Our devoted team is always there to serve you.