Menu

Close

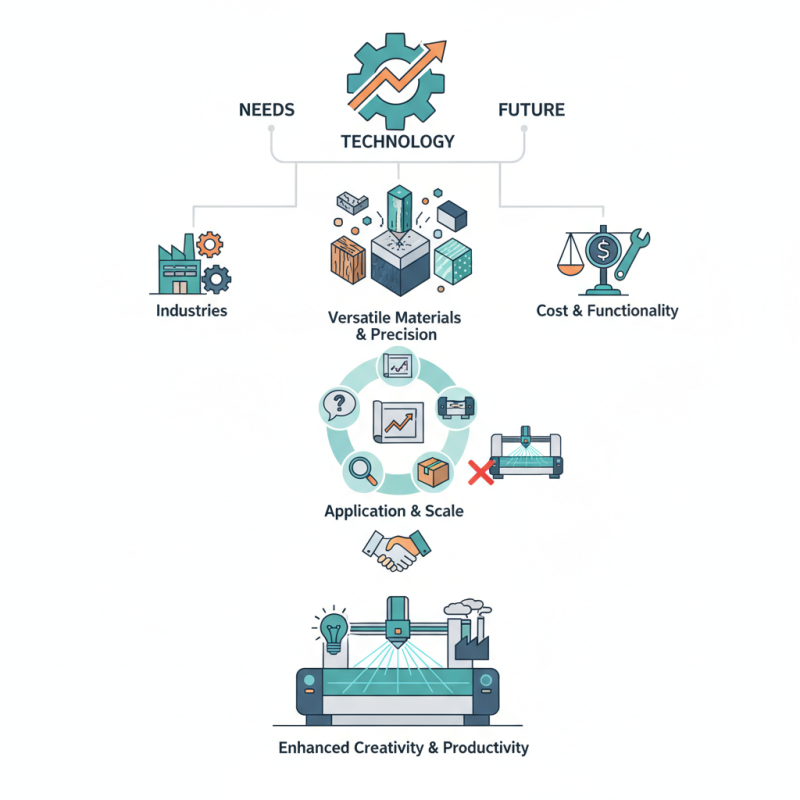

The demand for laser cutting machines is growing rapidly. In 2026, choosing the right machine is pivotal. Industries are embracing this technology for its precision and efficiency.

laser cutting machines offer versatility for various materials. They can cut wood, metal, fabric, and plastics with stunning accuracy. Yet, with numerous options, finding the best fit can be challenging. Each machine has unique features that cater to different needs.

Considering your specific application is vital. A high-end model may not be necessary for small projects. Mistakes happen in choosing machines that exceed requirements. Reflecting on what you truly need can guide your decision. Balancing cost with functionality is essential. In the end, the right laser cutting machine should enhance creativity and productivity.

Laser cutting technology has transformed various industries, from automotive to jewelry making. This process uses a focused laser beam to cut through materials with precision. According to a recent report by Research and Markets, the global laser cutting machine market is projected to reach $7.3 billion by 2026, highlighting its growing significance.

Applications of laser cutting are vast. It can work on metals, plastics, wood, and textiles. Industries benefit from its speed and accuracy, allowing for intricate designs. However, even skilled operators can face challenges. Material thickness and type may complicate the cutting process. Not every material reacts well to laser cutting. Some can warp, while others may burn.

Moreover, understanding the technology is essential for proper use. Operators must consider power settings and cutting speeds. A report from Statista indicates that around 20% of laser cutting operations require adjustments for optimal results. This need for constant monitoring leads to potential inefficiencies. Balancing quality and productivity remains a key concern in the field.

When selecting a laser cutting machine, the first aspect to consider is power. The machine's wattage affects its cutting speed and material thickness. Higher wattage is better for thicker materials. However, it may not be necessary for lighter work. This can lead to wasted energy and increased costs. Finding the right balance is essential.

Another critical feature is the cutting area size. Smaller machines save space but limit project sizes. Conversely, larger machines require more room but allow for bigger projects. Assess your workspace and the type of projects you want to undertake. You can end up overwhelmed if you choose a machine that is too large.

Lastly, consider the ease of use. Some machines come with advanced software while others require manual setup. Beginners may find complex systems frustrating. Look for user-friendly interfaces and good customer support. This can ease the learning curve. Remember, even the best technology can fall short without proper guidance.

| Feature | Description | Importance |

|---|---|---|

| Laser Type | CO2, fiber, or diode lasers available, impacting materials and precision. | High |

| Cutting Area | Dimensions of the work area; larger areas accommodate bigger materials. | Medium |

| Power Output | Higher wattage leads to faster cutting and the ability to handle thicker materials. | High |

| Software Compatibility | Compatibility with design software (e.g., CAD) facilitates workflow. | Medium |

| Cooling System | Essential for maintaining performance; types include air coolant and water chiller. | High |

| Safety Features | Includes automatic shut-off and ventilation to reduce hazards. | High |

| Price Range | Budget variations significantly influence options available. | Medium |

As the demand for precision and customization in manufacturing grows, choosing the right laser cutting machine becomes crucial. In 2026, several models stand out due to their performance and versatility. High-speed fiber lasers are gaining attention. They provide excellent cutting quality for various materials, from metals to plastics. Users appreciate how they can handle intricate designs effortlessly.

Another category includes CO2 laser machines, ideal for non-metal materials like wood and acrylic. These machines are recognized for their reliability and affordability. Many small businesses find them perfect for creating prototypes and custom products. However, operators often face challenges in calibration and maintenance. Frequent adjustments may be needed, which can disrupt productivity.

Also noteworthy are the hybrid models that combine features from both fiber and CO2 lasers. They promise to enhance efficiency and expand capabilities. Yet, some users report difficulties in transitioning between different cutting modes. These challenges highlight the importance of user training and understanding the technology. Opting for the best machine necessitates careful consideration of unique business needs.

In 2026, the landscape of laser cutting technology has evolved significantly. Different laser technologies offer unique advantages. CO2 lasers remain popular for their versatility and cost-effectiveness, ideal for cutting organic materials. Research indicates that CO2 lasers can easily handle materials like wood and acrylic. Their ability to produce intricate designs enhances their appeal in various industries.

Fiber lasers have gained traction too. These machines are efficient for metals, offering faster cutting speeds and reduced operational costs. The efficiency of fiber lasers can reach up to 30% more than their CO2 counterparts. However, they may not perform well on thicker materials. The trade-offs between speed and quality need careful consideration.

Another emerging player is the ultraviolet (UV) laser. UV lasers provide precision and are excellent for sensitive materials. They minimize heat impact, reducing the risk of material deformation. However, their higher initial costs can be a barrier for smaller operations. As industries continue to adopt diverse technologies, understanding the specific needs will steer the right choice. Ultimately, every technology has its strengths and limitations that require thorough evaluation.

Maintaining your laser cutting machine is crucial for achieving optimal performance. Regularly cleaning the lenses and mirrors can improve cutting precision. Dust and residue can build up, affecting the beam quality. A simple soft cloth can work wonders. However, make sure not to scratch the surfaces.

Checking the alignment of the laser is also essential. Misalignment can lead to uneven cuts. This process might take some time, but it’s worth the effort. Remember, even a small deviation can create errors. Schedule routine checks to avoid costly mistakes.

Also, don’t overlook software updates. Keeping your machine's software current ensures you have the latest features and bug fixes. Sometimes, updates might introduce new functionalities that you didn’t know you needed. Embrace the learning curve that comes with these changes, as it can enhance your cutting capabilities significantly.

We offer Packaging Boxes delivered to your door. Secure, professional, and affordable, our custom made packaging boxes are guaranteed to protect and transport your valuable items. Our devoted team is always there to serve you.